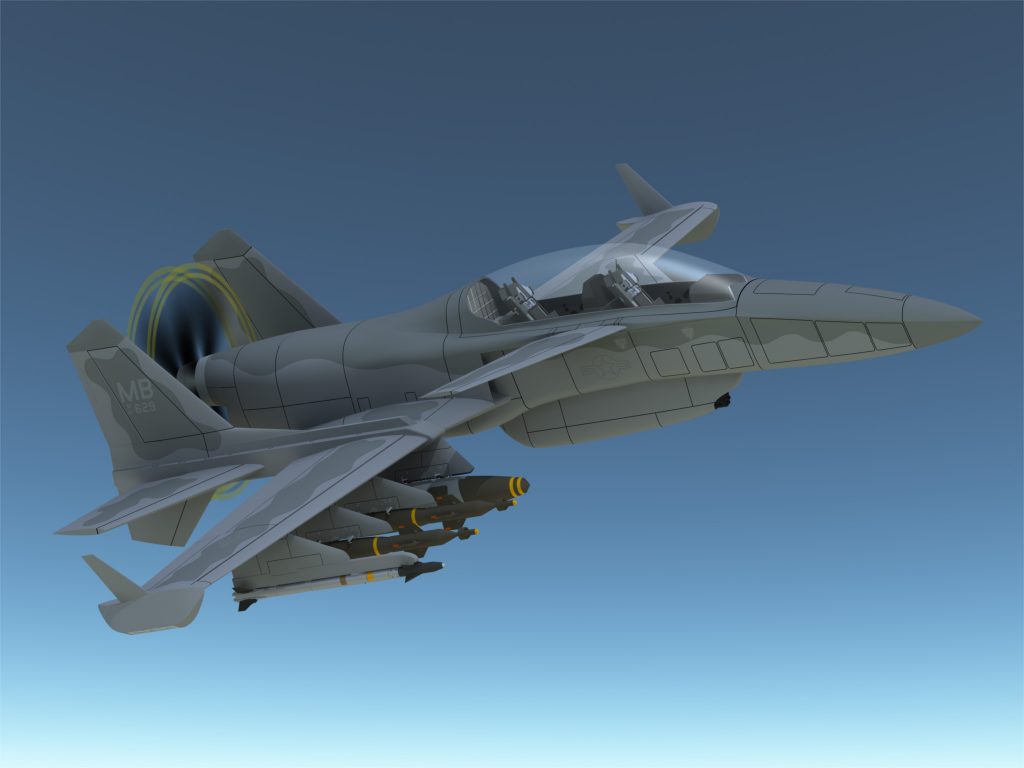

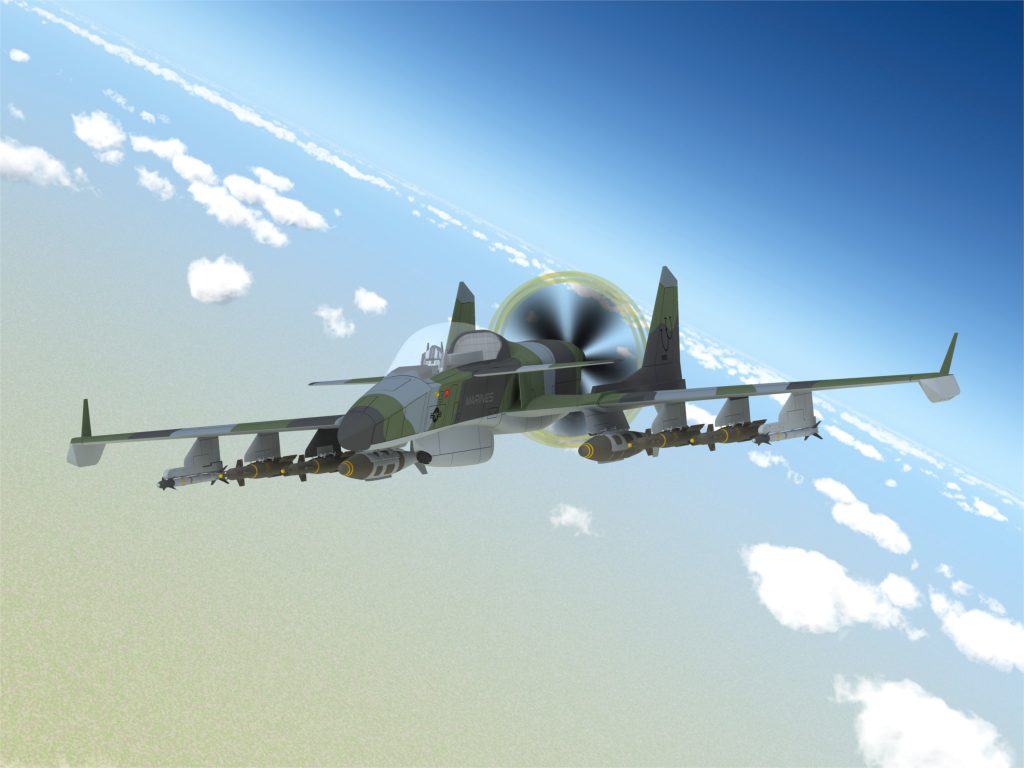

The Basic Per Unit Flyaway Cost (Flyaway Cost) of SM-27 Machete aircraft will be approximately $20,000,000 (twenty million) United States Dollars (USD), depending upon specific model and configuration.

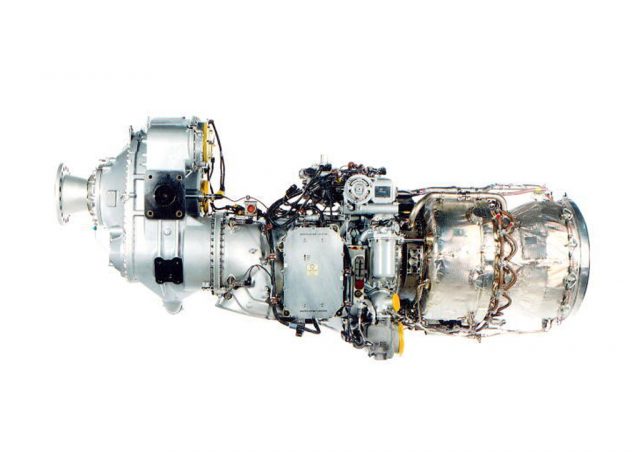

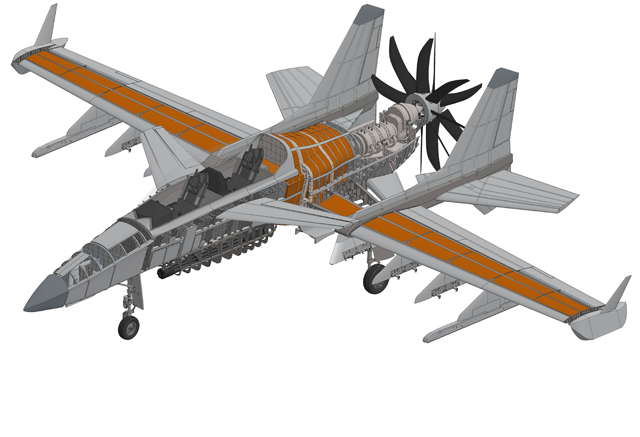

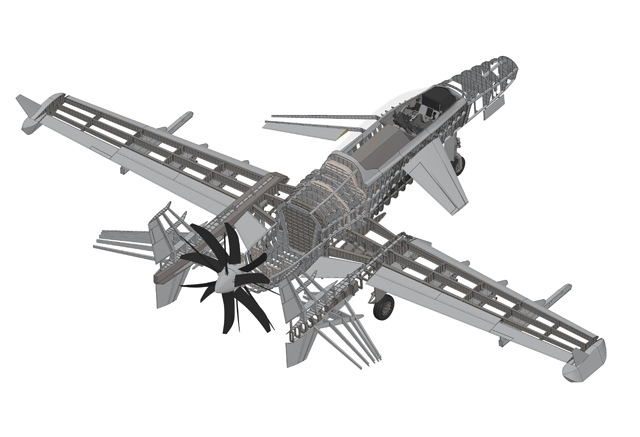

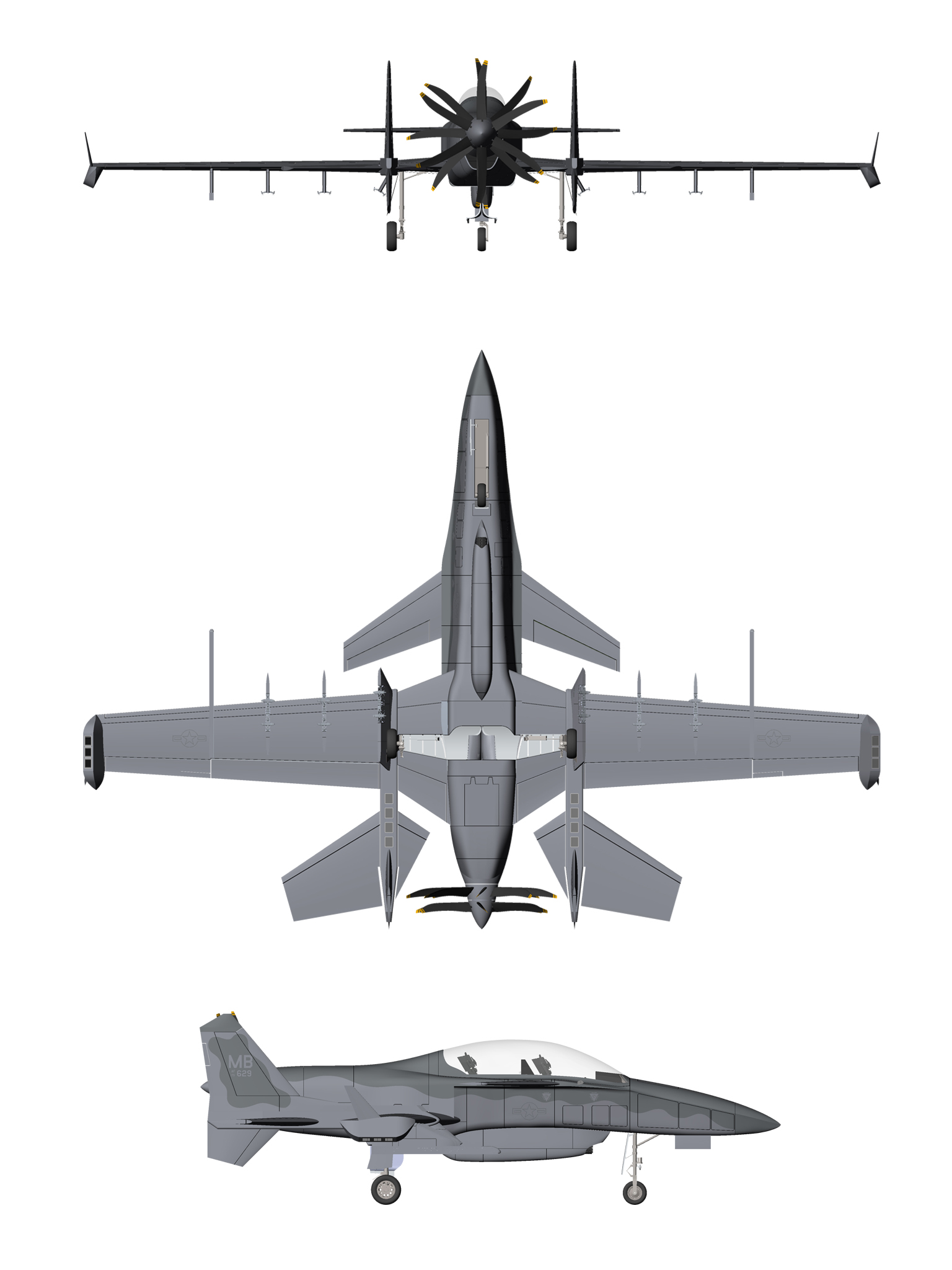

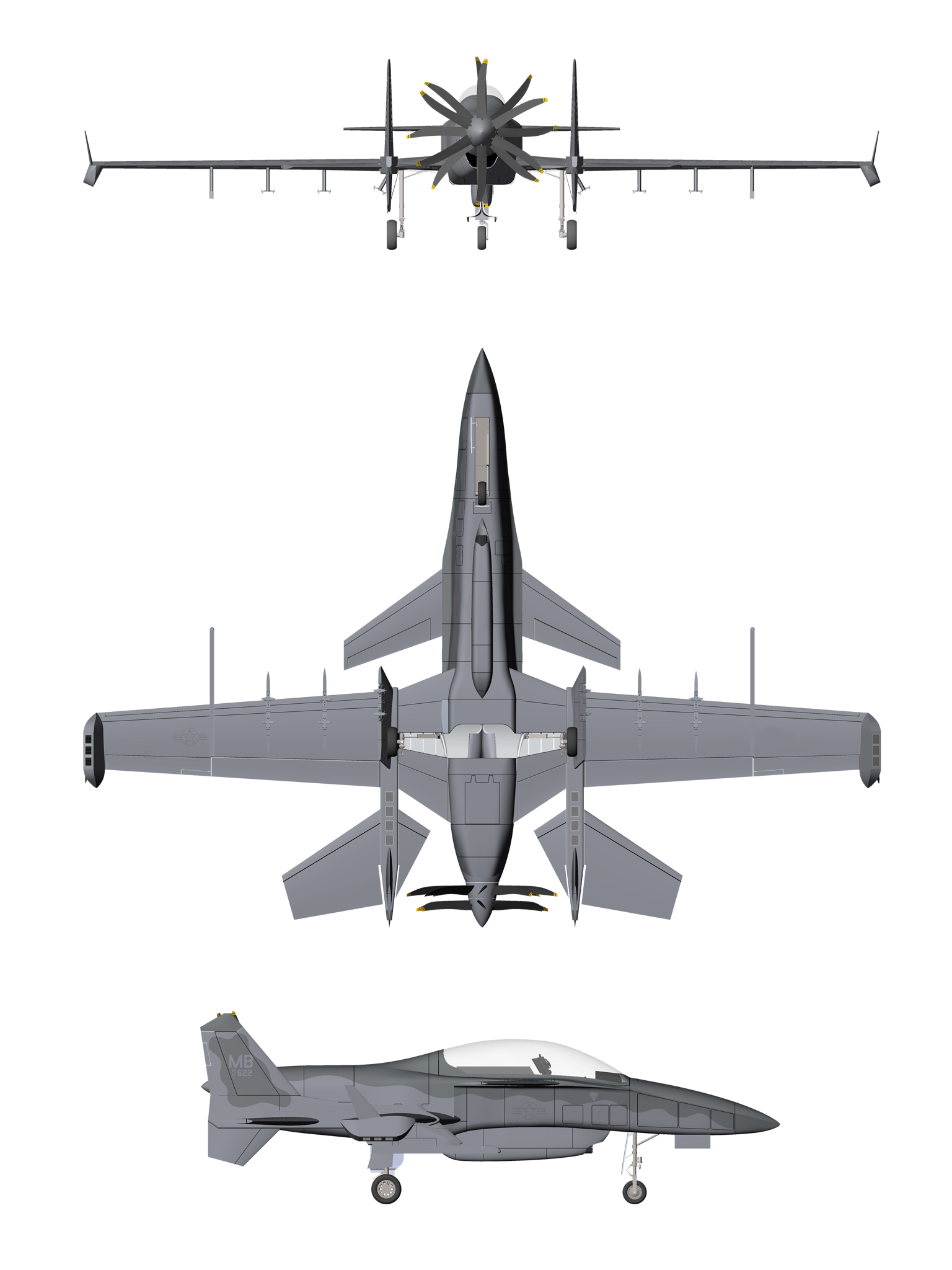

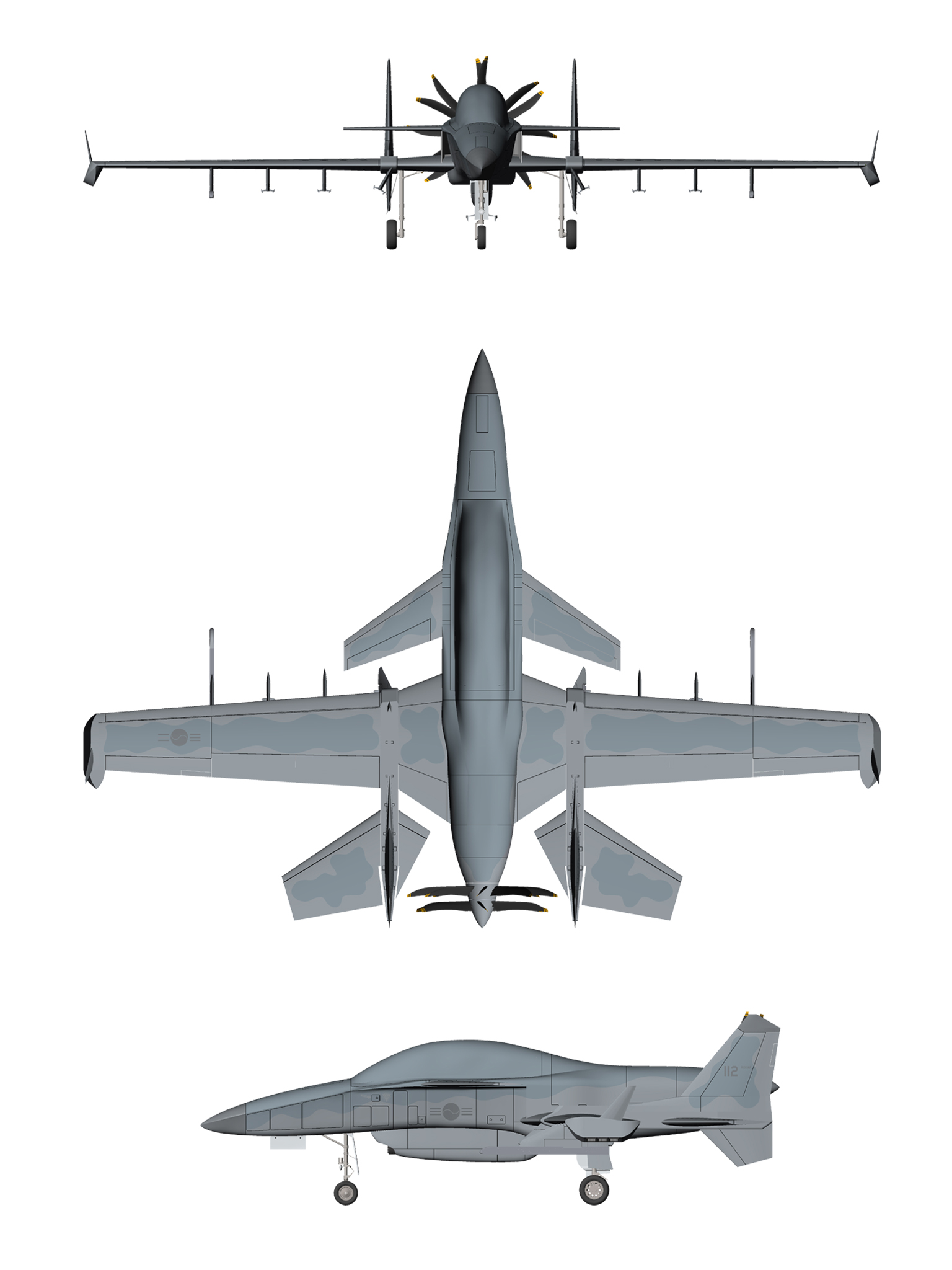

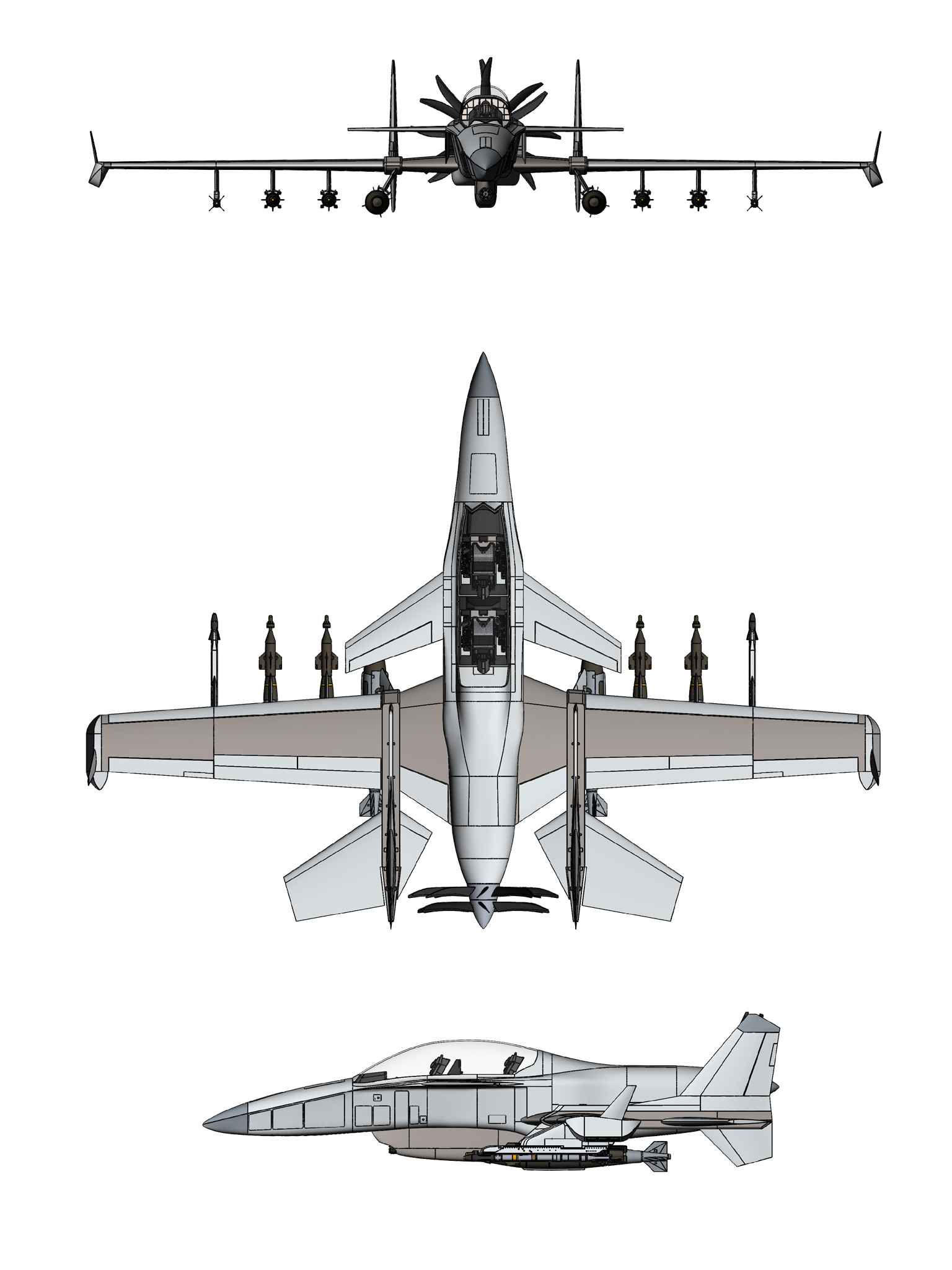

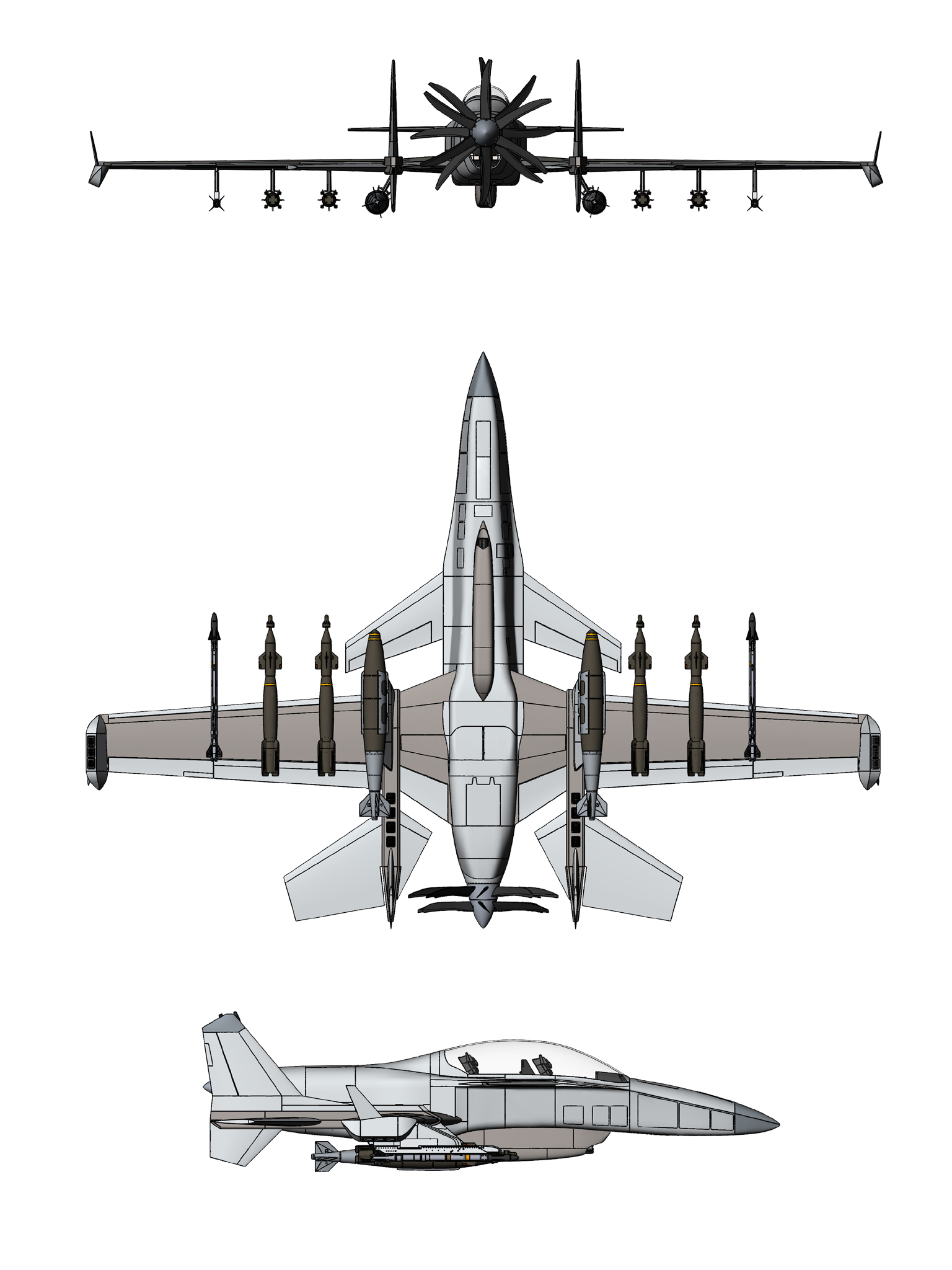

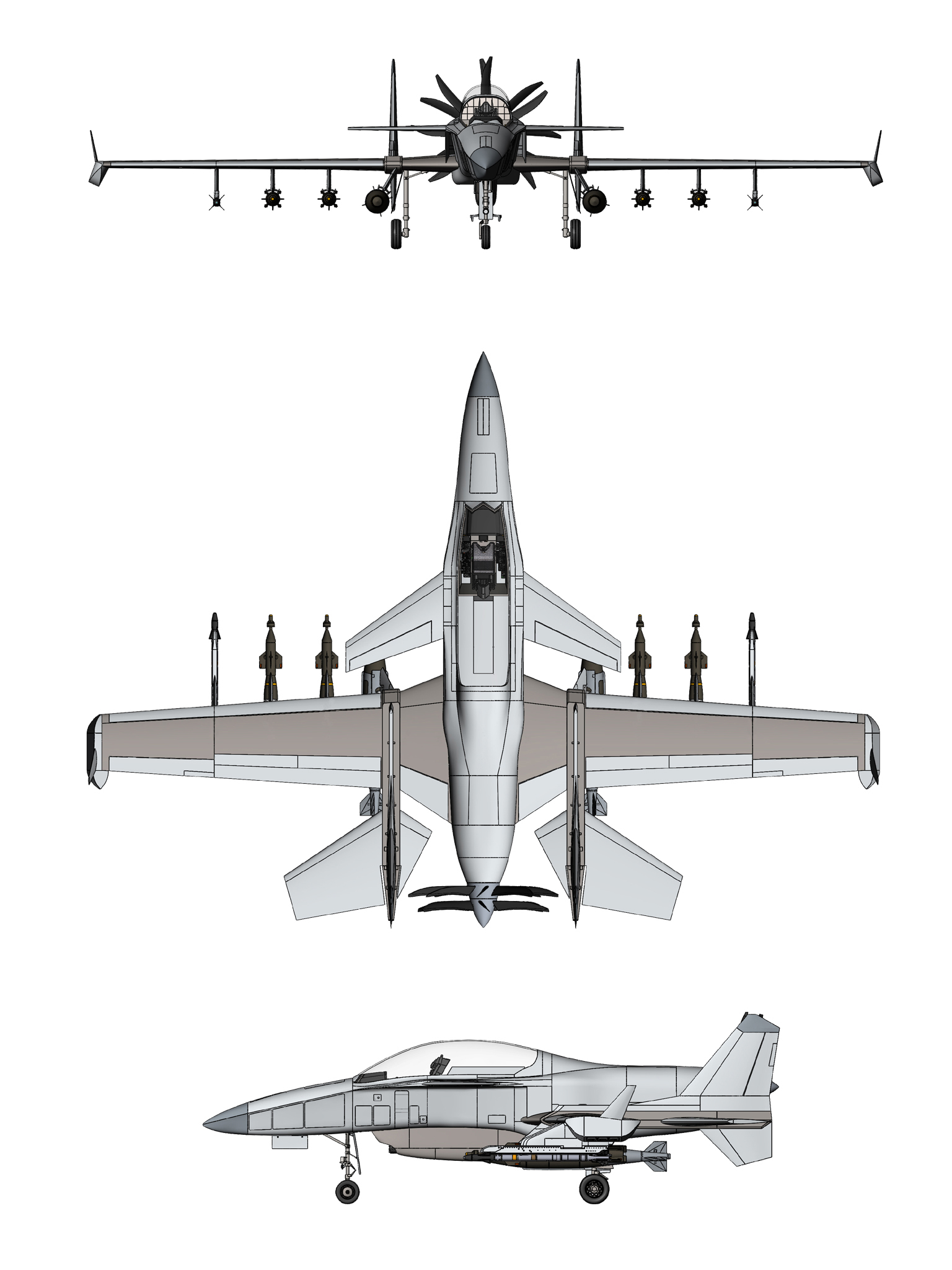

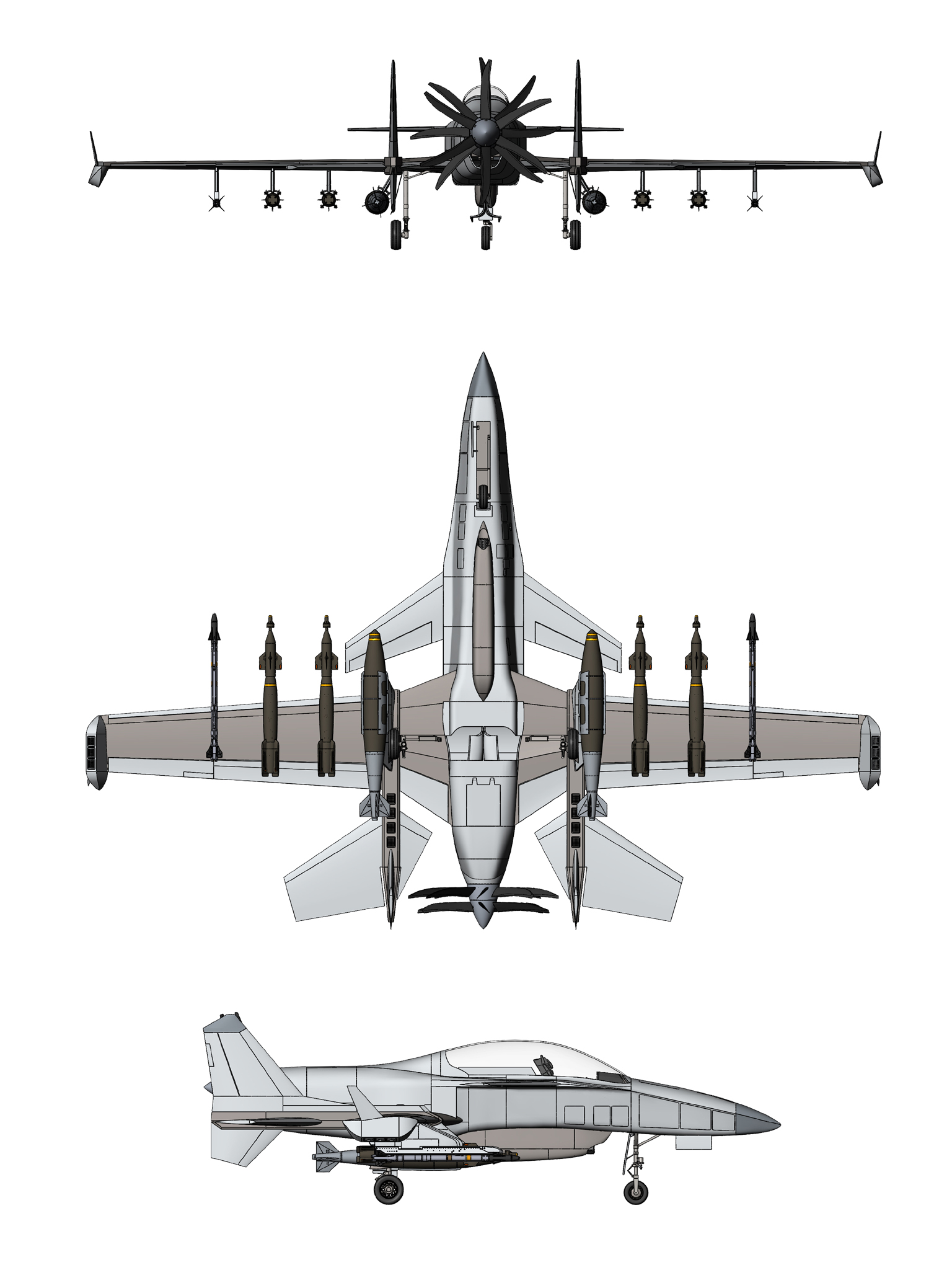

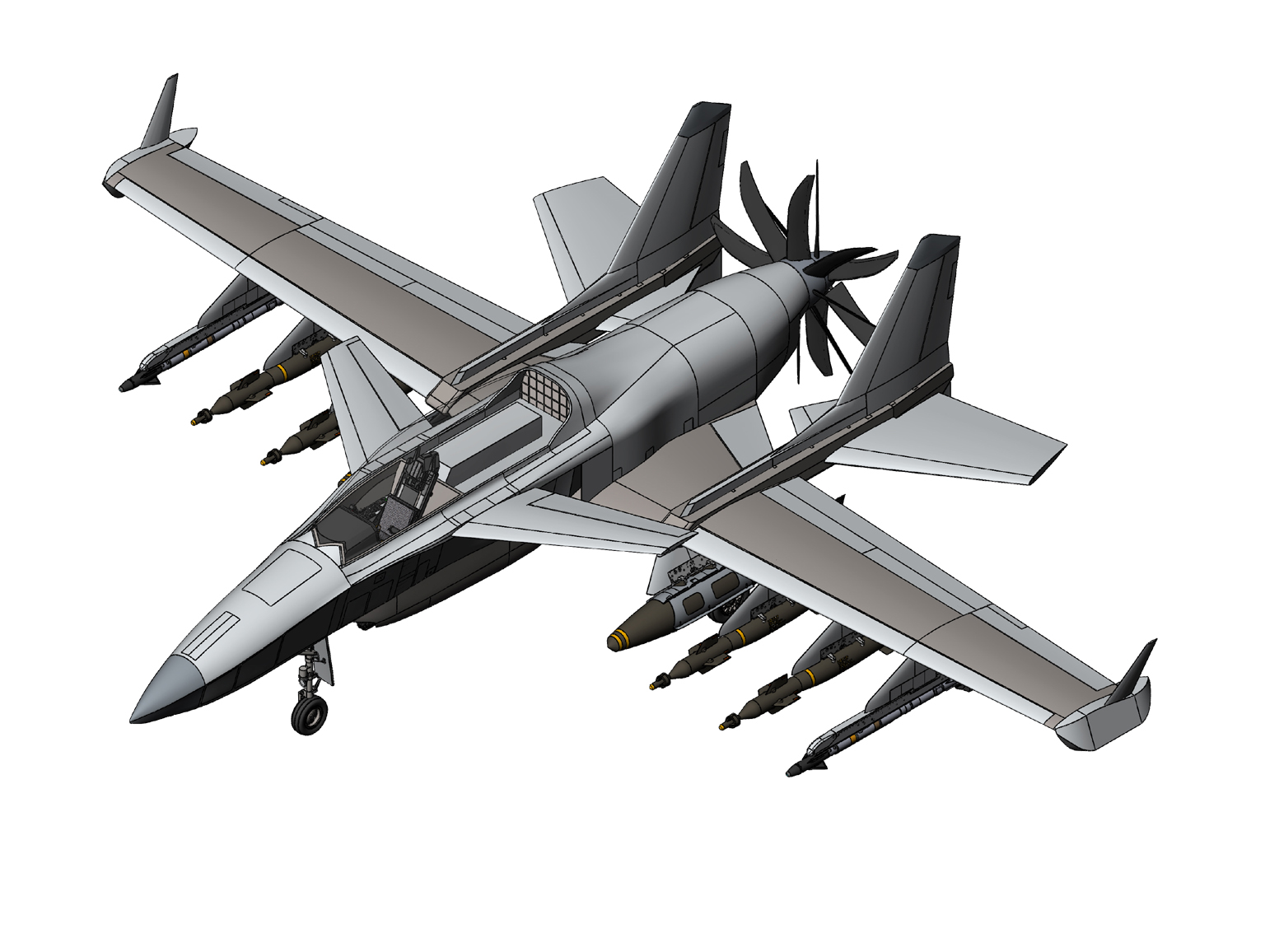

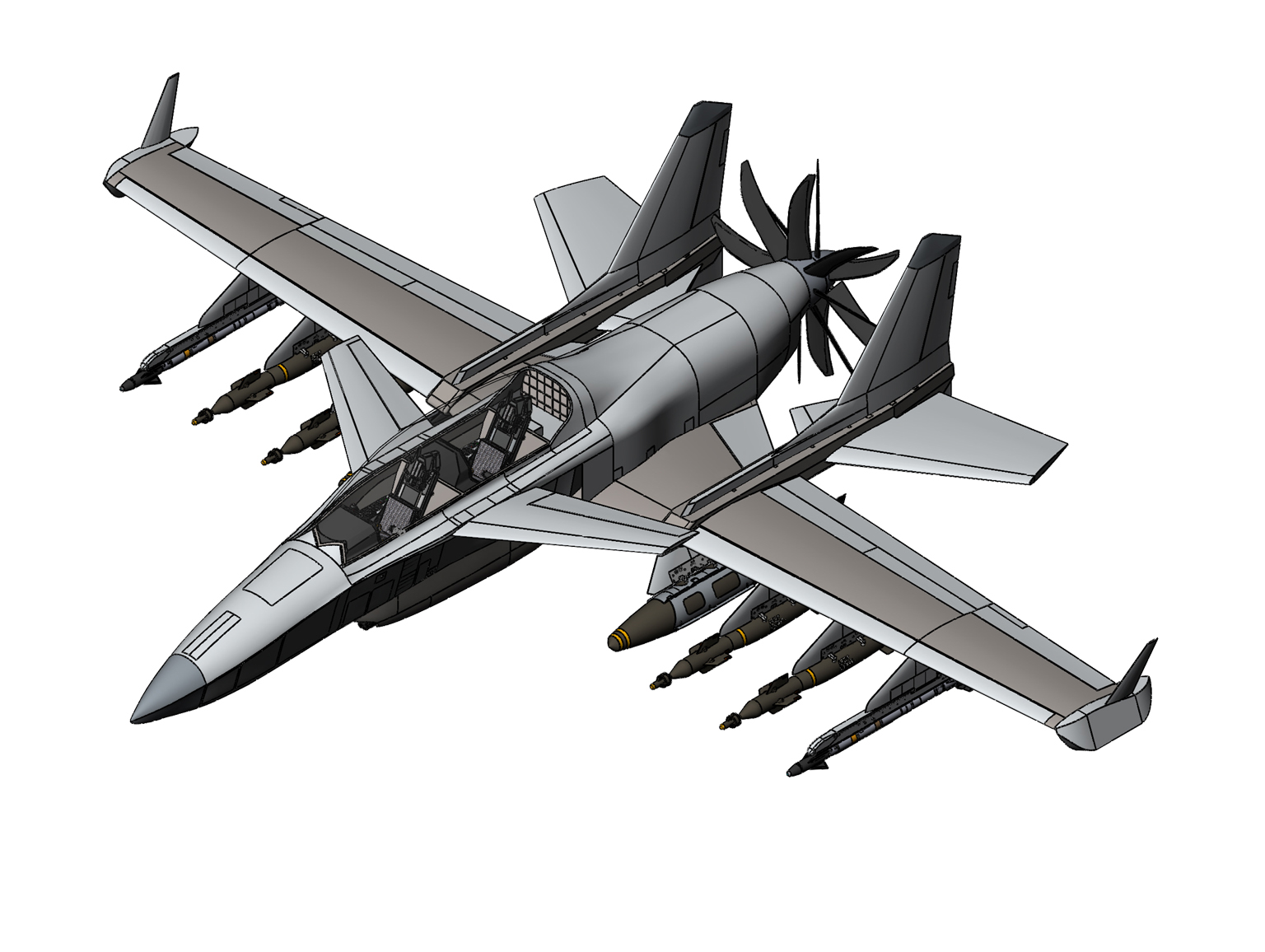

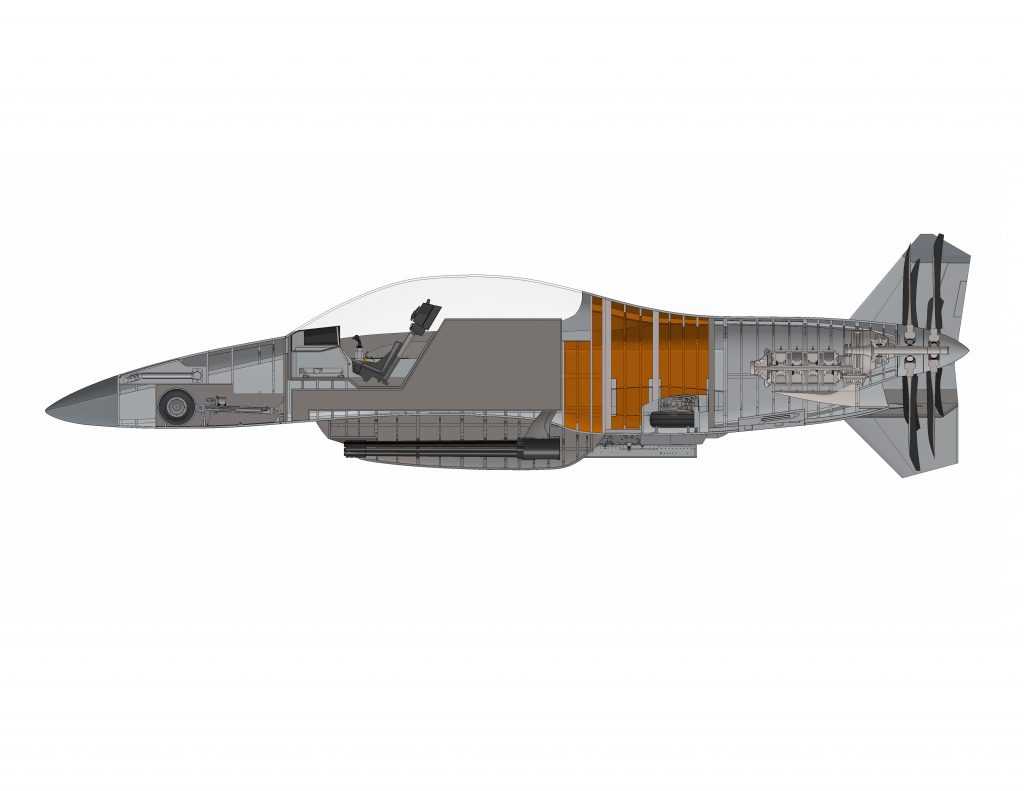

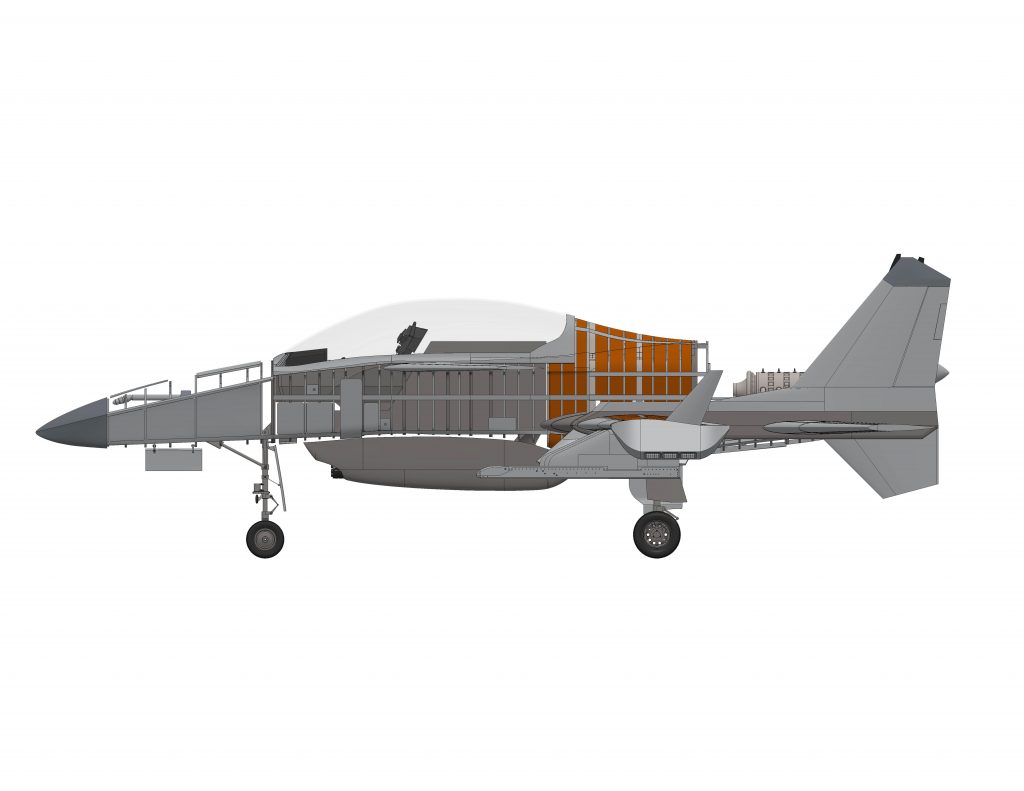

This ROM, approximate Flyaway Cost apply to one (1) basic Turboprop Machete platform (Stavatti Model 27 S or T) of Standard Weapon System Configuration (SWSC). In an effort to simplify the marketing and distribution of the Machete weapon system worldwide, Stavatti has developed the SWSC. The SM-27S/T SWSC represents a common SM-27S/T configuration which is readily suitable for mass production and expedient delivery to the customer. Stavatti customers may purchase SM-27S/T SWSC aircraft at a specified flyaway cost plus applicable duties and export/delivery expenses.

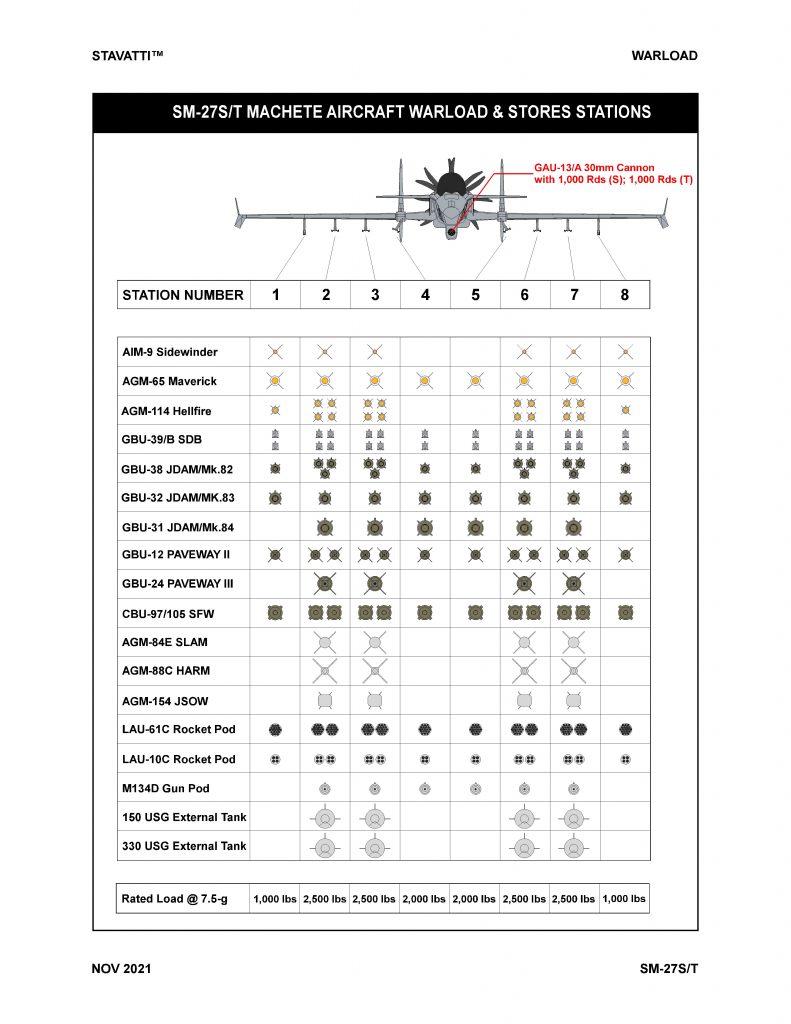

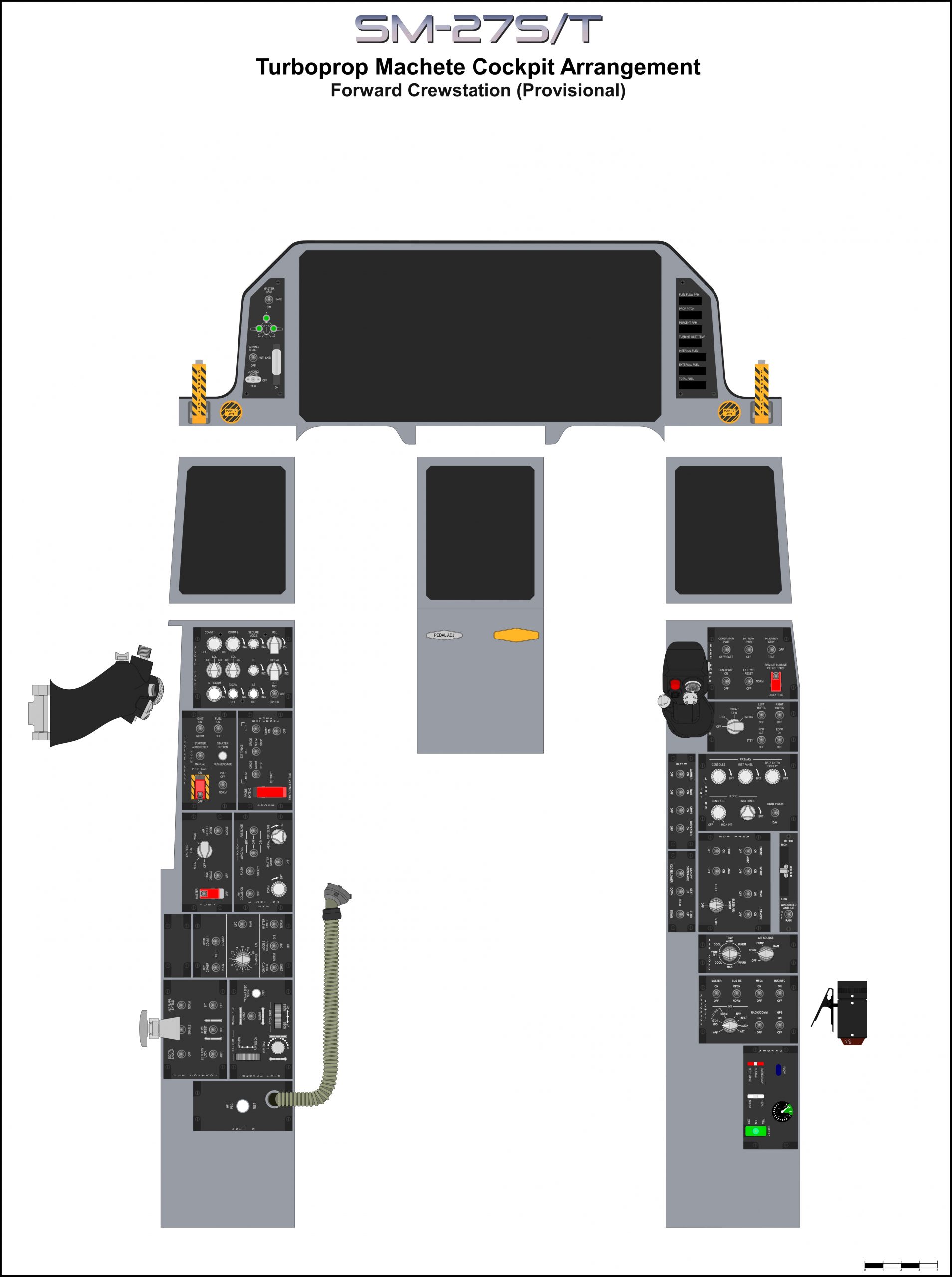

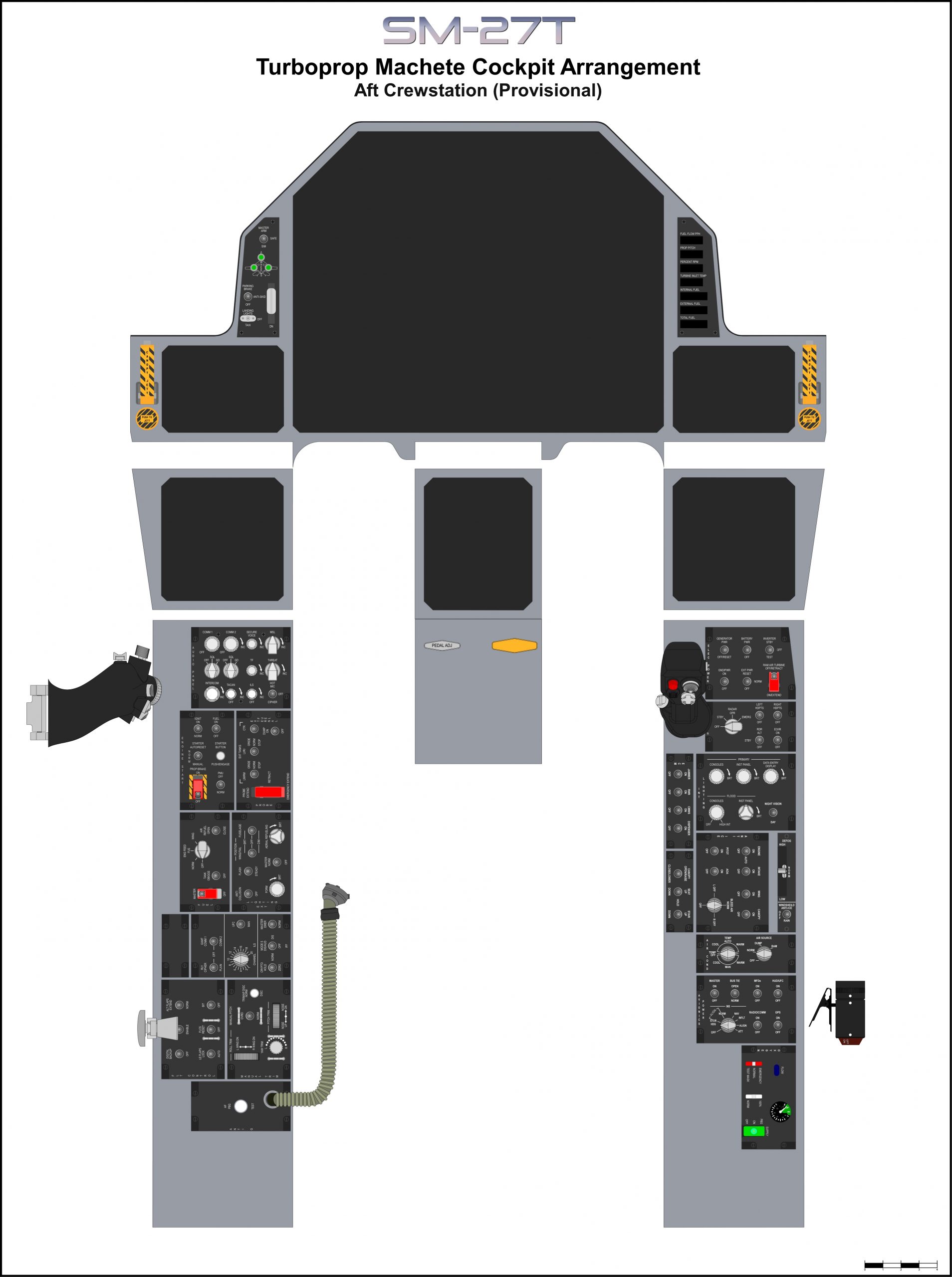

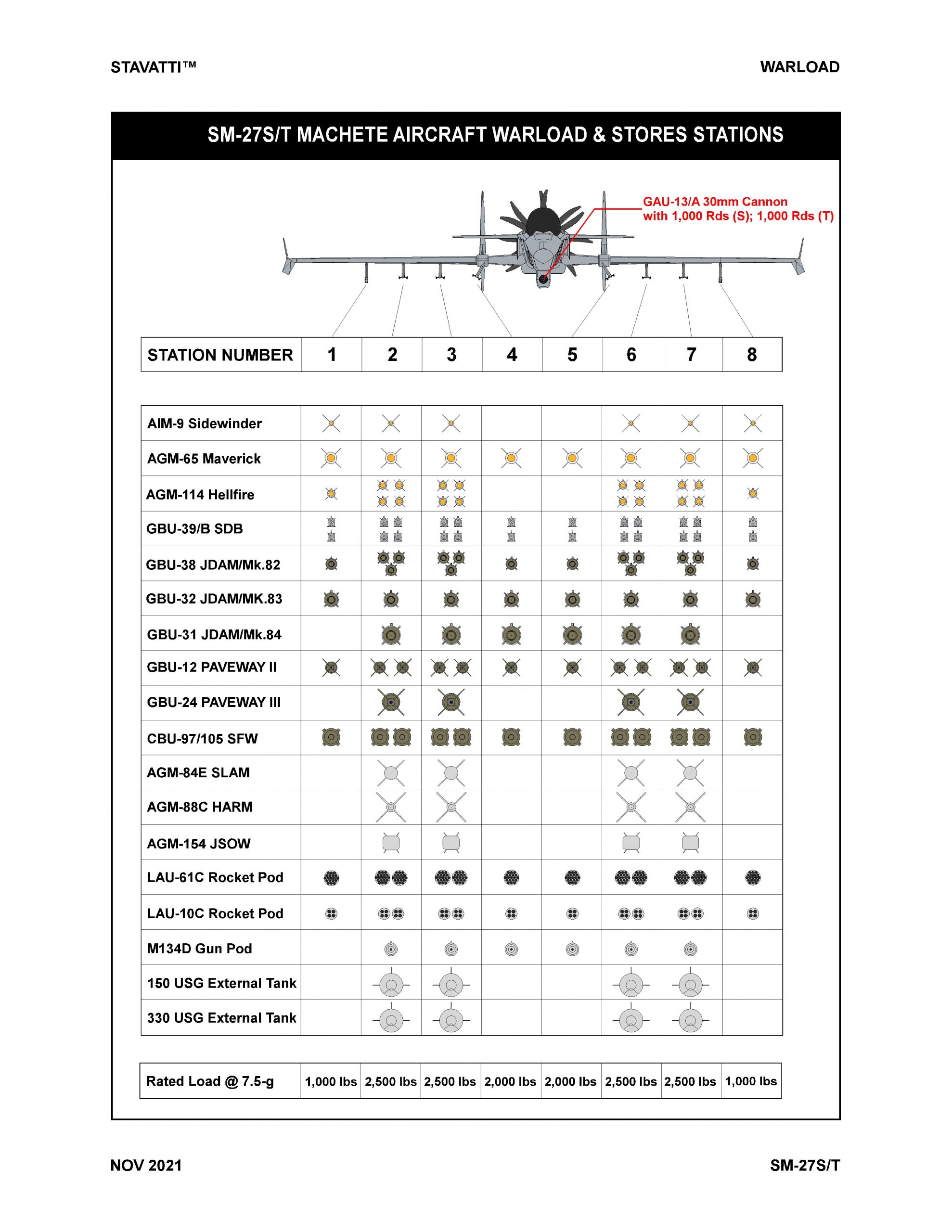

SM-27S/T SWSCs are specified within the SM-27S/T Configuration Control Statement (CCS) document as issued by Stavatti Aerospace for specific Machete models as appropriately configured for specific domestic and allied customers. Contact Stavatti or visit Machete Product Literature for a copy of an appropriate CCS. A portion of the avionics, displays, armament and related systems associated with the SM-27 SWSC are also indicated in the Machete Specifications page of this website. The following support documentation, options, equipment and material is also included with each SM-27S/T of SWSC:

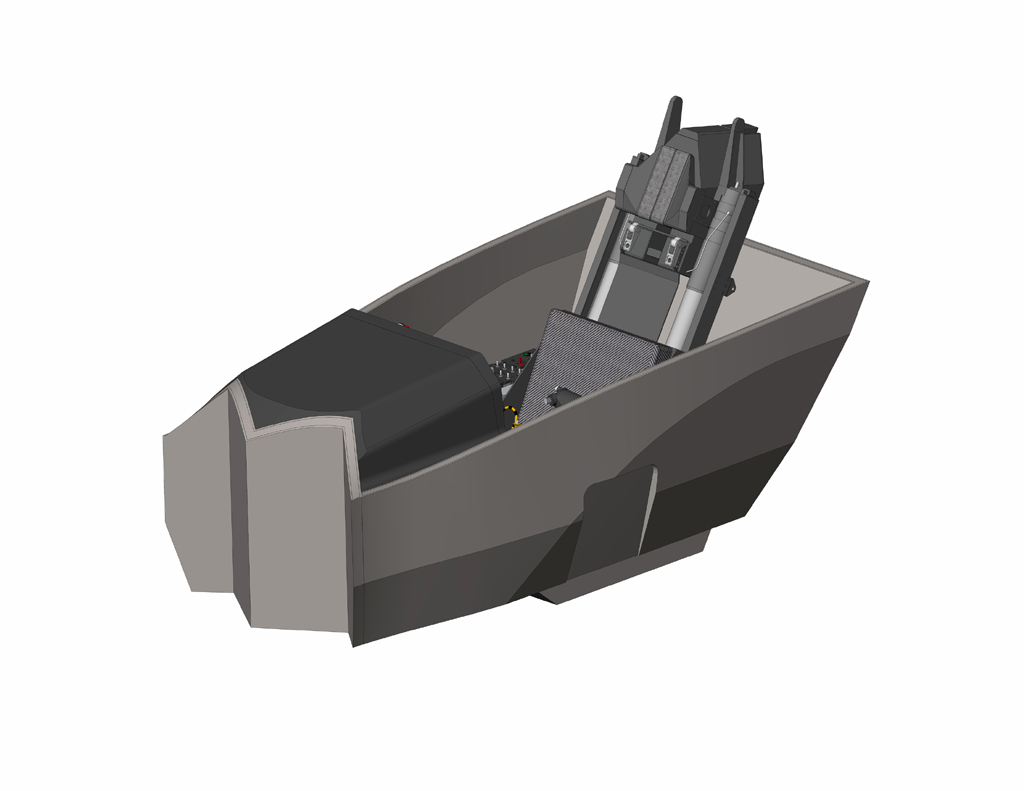

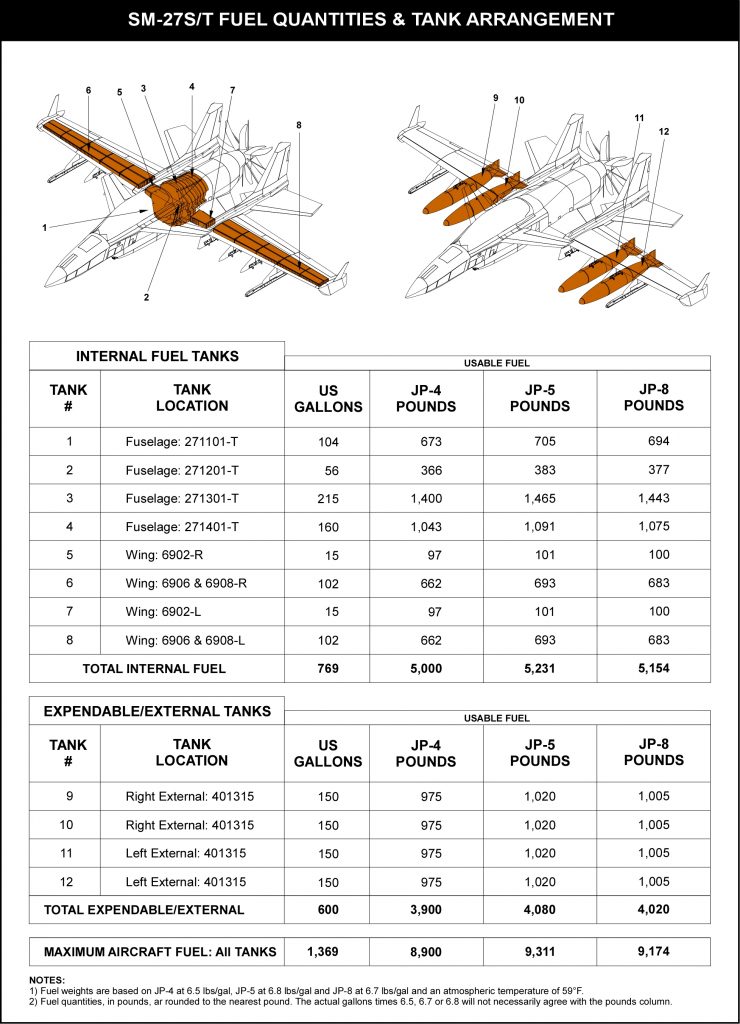

U.S. Standard Airworthiness Certificate, Export Certificate of Airworthiness, Weight and Balance Data Sheets/Weight and Balance Plotter, Aircraft/Engine/Armament System Log Books, Abbreviated Checklist, Flight Manual, Pilot‘s Operating Manual, Avionics Wiring Diagrams, Hydromechanical Systems Manual, Maintenance Manual (Airframe), Illustrated Parts Catalog (Airframe), Wiring Diagram Manual (Airframe), Weight and Balance Manual, CAS Air Combat Manual, COIN Air Combat Manual, Special Combat Operations Manual, Advanced Training Instructional Manual (SM-27T), Component Maintenance Manual, Structural Repair Manual, System Control Code Programmers Manual, Illustrated Tool and Equipment Manual, Nondestructive Inspection Manual, Engine Maintenance Manuals, Engine Illustrated Parts Catalogs, Parts Warranty Listing, additional miscellaneous information concerning engine, airframe, avionics and armament support, Aircraft Tie-Down Kit (including tie-down anchors and cable, wheel chocks, control locks, pitot-static port covers, etc.), Aircraft Full Canopy Sunshade/Cover, Basic Aircraft Tool Kit, Aircraft Emergency Survival Kit, HGU-86/P pilot flight helmet and accompanying flight/anti-g suit of customer specified sizing (Note: SM-27T/JT aircraft include two helmets and anti-g suits), 24 hours of Stavatti provided SM-27 operational ground schooling/orientation for one flight officer, 24 hours of Stavatti provided SM-27 maintenance and service ground schooling/orientation for one maintenance officer, 5 hours of SM-27 orientation flying in a Stavatti owned and operated SM-27 for one flight officer, Custom Paint Scheme consisting of up to 10 base colors and up to 25 trim colors as well livery/noseart, 675 or 470 (model dependent) rounds of installed 30 mm ammunition for GAU-13/A cannon, Full Fuel consisting of 5,000 lbs of JP-8 installed in aircraft, additional equipment and a 2,000-Hour ‘Nose-to-Nozzle’ Manufacturer’s Warranty.

All publications, documents and manuals will be provided in both hardcopy bound print as well as CD-ROM and Aerofiche format. In addition to documentation supplied by Stavatti Military Aerospace, additional documentation may be provided detailing the operation/maintenance of specific aircraft systems by specific aircraft system manufacturers. Stavatti will provide Service Bulletins, Service Letters, Air Worthiness Directorates and manual revisions for the duration of aircraft operational service life.

The Flyaway Cost of the SM-27S/T does not include the cost of any spares, external stores/armament, or other logistical support that may be associated with a weapon system procurement contract. The additional costs associated with the provision of spares, external stores/armament, Contractor Logistical Support or any other indicative cost options, maybe provided by Stavatti. All Flyaway Cost data provided herein is not contractually binding and are conceptual in nature.

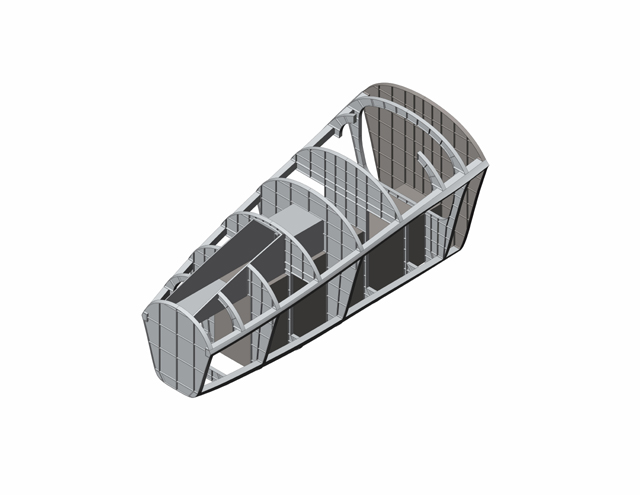

The noted Flyaway Costs only apply to the SM-27S/T of SWSC. The SM-27S/T SWSC does not represent aircraft configured to satisfy specific customer requirements. Stavatti desires to satisfy all customer needs and requirements. In so doing, the SM-27S/T will employ open avionics and systems architecture allowing the SM-27S/T platform to employ a wide variety of avionics, armament and sensor systems. Customers are invited to procure aircraft which employ customized systems configurations, as specially developed by Stavatti. The Flyaway Cost of SM-27SS/T aircraft of customized configuration will be dependent upon the systems specified and is determined only upon assessment of the specific configuration.